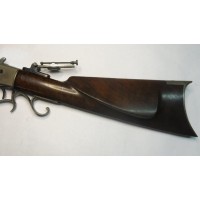

Tisdel Swivel Breech Rifle Serial number 287 .32-40 WCF

Tisdel Swivel Breech Rifle

Serial number 287

.32-40 WCF

SOLD - $2495

Luther Weston Tisdel was a gunsmith in Scranton, Pennsylvania. He was born on July 25, 1829 in Lake Ariel, Wayne County, Pennsylvania. He died on February 19, 1906 in Scranton, Lackawanna County, Pennsylvania. The first known mention of him was in the 1861 Scranton City Directory as a machinist. He lived at 925 Slocum Avenue with his wife Anna and four children, Theodore, Frank, Arthur and Jennie. He moved his shop several times but was always just off of Lackawanna Avenues commercial district. 104 Penn, 112 Franklin, 118 Franklin, 120 Franklin and 92 S. Wyoming. The 1880 City Directory read: “L.W. Tisdel, Manufacturer and Dealer in Guns, Pistols, Ammunition, etc. Repairing of all kinds promptly attended to and satisfaction guaranteed.” His logo was two crossed muskets flanked by two pistols and a powder horn hanging from the rifles. He was actively in business from 1848 to 1891 in Scranton. Mister Tisdel was 77 years old and in the last year of his business when he made this rifle.

The top of the barrel is marked with the serial number 287 and L.W. TISDEL / SCRANTON PA / CAST STEEL. The lower tang is also marked with the serial number. The left side of the lower tang is marked 1891 and is only visible after the butt stock has been removed.

The tang sight may be a modified 1885 Bullard mid-range with a thick base. The left side of the staff has a linear scale that is 1.8” in length and marked from zero to 90 by 10’s. The distance between each multiple of 10 is .200”. Each individual mark between the numbers is .020”. There is no vernier scale on the slider, only a single mark. The adjustable range is from a little below zero to about 66. There was a screw missing in the left side of the base that could be used to lock the staff in a vertical position. A replacement facsimile has been fabricated and installed. The eye cup appears to be able to utilize different sized aperture disks. The disk that is installed is frozen in place and no attempt has been made to remove it.

The tubular globe front sight and the barrels rear sight have not been identified and are most likely proprietary. The barrel sights leaf is spot welded to its dovetail. Spot welding came into practical use in about 1880. The front sight is slightly bent down at the front but does not cause any sighting problems.

The barrel is 29 7/8” long. Measurement across the flats at the breech is 1.010” and at the muzzle it averages .725”. The barrels rifling has a 6 groove 13” right hand twist. The bore diameter is .320”. The groove diameter is .326” at the breech and .325” at the muzzle. The muzzle has been re-cut flat 90 degrees to the bore due to corrosion and a dent at the rifling edge. The barrels rim rebate measures .067” x .520”. The .32-40 WCF cartridge was introduced in 1884.

The forward portion of the trigger guard that screws into the receiver was broken off. It was repaired by drilling and tapping through the broken threaded portion and into the guard’s bow and affixed with a screw. The screws end is contoured to the inside of the trigger bow where it protrudes.

The butt stock has two 1/2” diameter bored holes that are 3 3/4” deep under the butt plate. The right side of the butt stock has a diamond shaped inlay that is 1” by 5/8” and located 5” rear of the receiver. This does not appear to be a damage repair or decoration and may be original to the stock’s fabrication by covering a flaw in the wood.

On the bottom of the barrel, 2.35” from the muzzle, is a shallow dimple .20” in diameter whose purpose is unknown. It is slightly off center and appears to have been made with a drill bit. There is also some minor damage to the octagonal edges in this area as well as some surface pitting.

The firing pin was an improperly dimensioned mild steel replacement. A firing pin has been fabricated and installed. The pins rebound spring was replaced for better function. There is .048” tip protrusion.

This rifle’s firing mechanism works differently than most other single shot rifles. The components are the hammer, trigger and firing pin with their associated springs. There is no half cock or safety notch in the hammer. In the full cock position the hammer is under tension from the main spring. The trigger is pulled releasing the hammer. Just before the hammer reaches the firing pin the hammer is no longer under main spring tension and is moving by inertia and has enough momentum to continue forward, striking the firing pin and driving it forward. After firing, the hammer rebounds and is in an unrestrained condition and moves freely. Trigger pull is between 2 lb. 3 oz. and 2 lb. 5 oz. If your thumb slips off the hammer when cocking the rifle will fire.

There is an adjustment for the swiveling action, between the receiver and barrel, under the forend wood.

When taking the rifle apart the side plate screw was loose. When putting the rifle back together the hammer bound up by being pinched between the right side of the receiver and the side plate when the side plate screw was tightened. The exact reason is speculative but with stoning, lapping and polishing the problem was eliminated.

Placed masking tape shims on the underside of the forend wood to compensate for wood shrinkage so its contoured screw head could properly align.

Weight is 8 lb. 9 oz

Overall length is 45 13/16”