Springfield Armory Model 1868 Experimental Nickel Plated Rifle

Springfield Armory Model 1868 Experimental Nickel Plated Rifle

Serial Number 38997

.50-70

In January of 1869 the Ordnance Department entered into a research project with an intent to protect rifles from corrosion by performed several experiments using nickel plating. Nickel plating was a new technology at the time. The first attempt was for various parts and equipment plated by Quintard Ward & Co. in New York in February of 1869. A second attempt was performed shortly after on all parts of an 1868 rifle by Remington Nickel Plating Co. in Boston, Mass. Another in December of 1869 by the George Allen Co. of Boston.

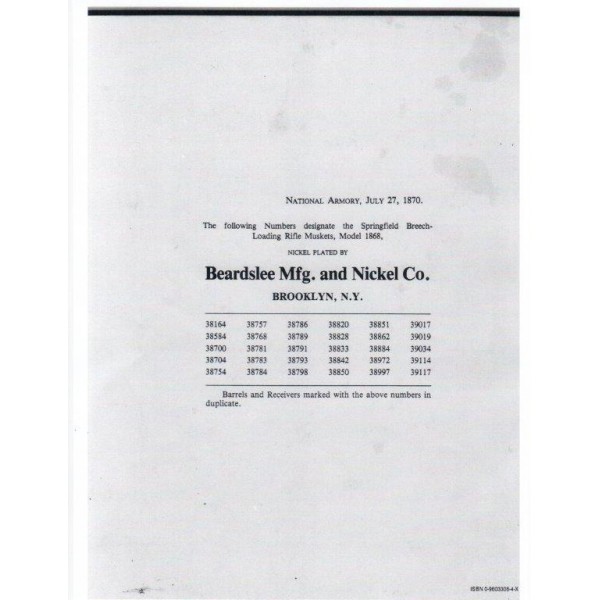

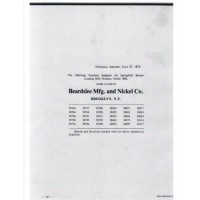

On May 25, 1870 thirty 1868 rifles were sent to E. H. Bailey Co. in Philadelphia to be plated. On July 27, 1870 thirty were sent to Beardslee Mfg. & Nickel Co. in Brooklyn, N.Y. as well as the Union Nickel Co. in Boston, Mass. A cost of $3.00 was charged for each. After this, Springfield Armory plated thirty more themselves for a total of 120.

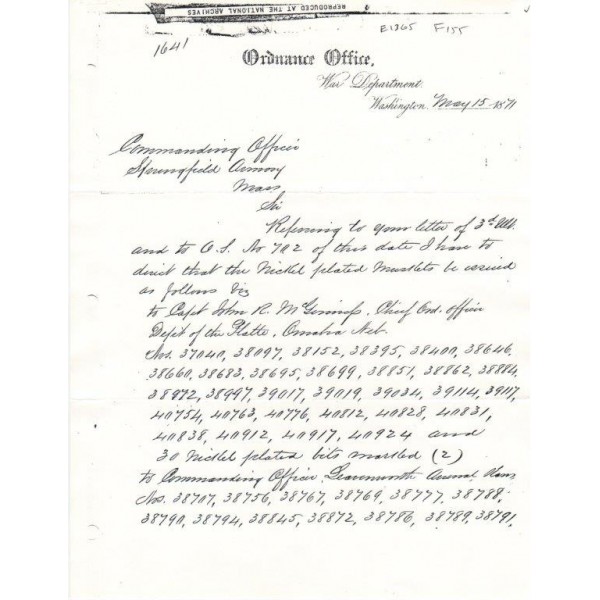

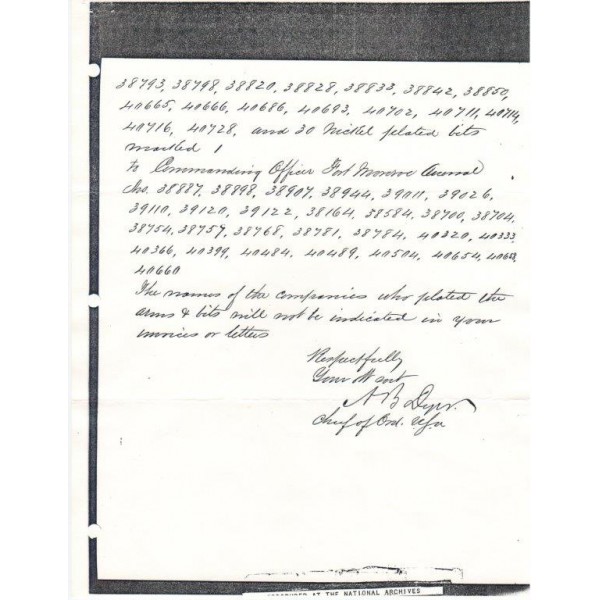

A decision was made by Major General Alexander Brydie Dyer, Chief of Ordnance, on May 15, 1871 to issue thirty each of the commercially plated rifles to the following for trial purposes:

1) Captain John R. M. McGinness

Chief Ordnance Officer

Department of the Platte

Omaha, Neb.

2) Commanding Officer

Leavenworth Arsenal, Kansas

3) Commanding Officer

Fort Monroe Arsenal, Virginia

Photocopies of paperwork that accompanies this rifle:

1) A copy of General Dyers order for field trials dated May 15, 1871. It is addressed to Commanding Officer, Springfield Armory (Colonel James Gilchrist Benton).

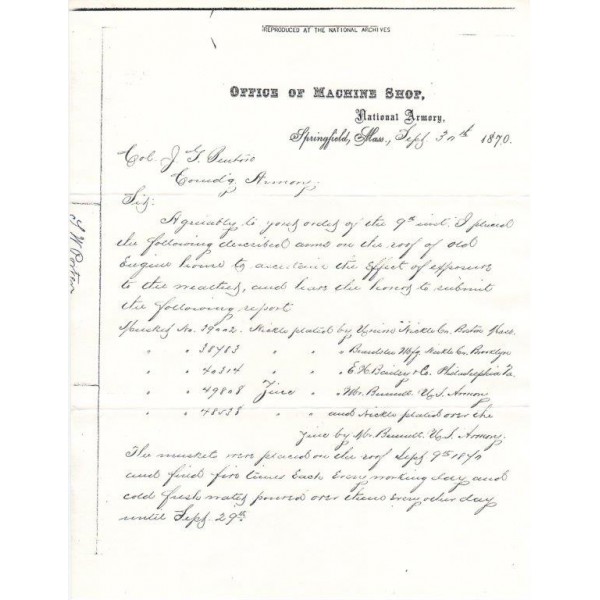

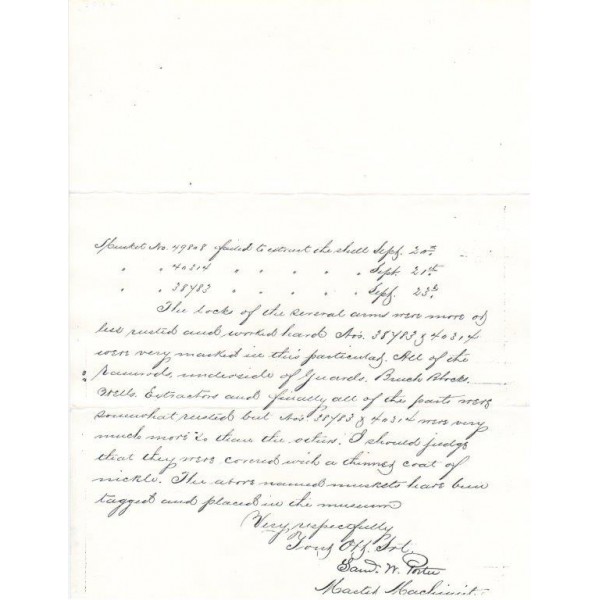

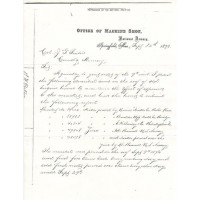

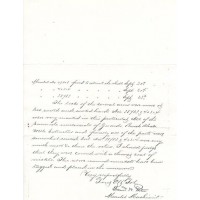

2) A copy of a letter from the Office Of Machine Shop describing tests performed to access the durability of the nickel plating. It is addressed to Colonel J.G. Benton and dated Sept. 3, 1870 and signed by Samuel W. Porter.

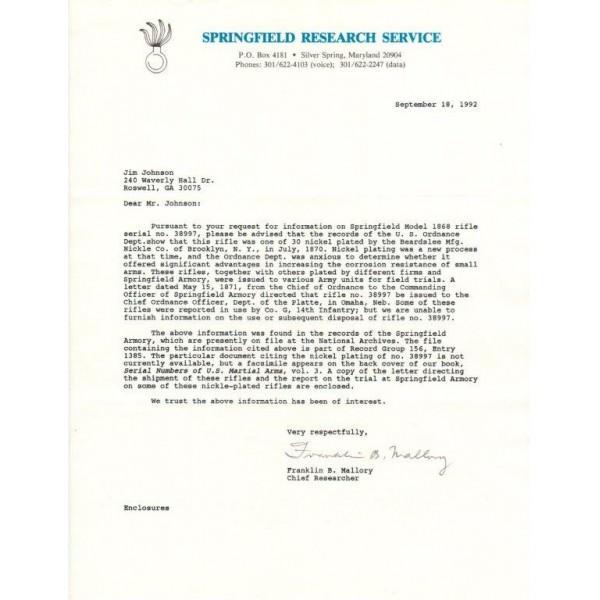

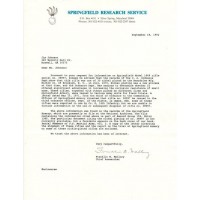

3) There are two letters from the Springfield Research Services signed by Frank Mallery. One is dated Sept. 5, 1992 and the other is dated Sept. 18, 1992. Both are addressed to Jim Johnson, 240 Waverly Hall Dr., Roswell, Ga 30075. The second letter contains a little more information than the first.

4) A copy of the back cover of the Springfield Research Services, Volume 3, “Serial numbers of U.S. Martial Arms”. It is a list of the thirty rifles plated by Beardslee Mfg. & Nickel Co.

This rifle is listed twice in the SRS books. Volume 1, page 4 stating 68R 072770 NICKEL PLATED (BEARDSLEE) and Volume 3, page 7 stating 68R 051571 TO DEPT OF THE PLATTE

This rifle was plated by the Beardslee Mfg. & Nickel Co. in Brooklyn, N.Y. Some sources state the barrels were marked above the serial numbers with B. M. & Co. This is apparently not totally correct since this rifle is not so marked. Some examples are known to be so marked.

The breech block is marked with 1870 / eagle head / crossed arrows / US. It is the thicker 1868 version.

The lock plate is marked with the eagle motif and U.S. / SPRINGFIELD forward of the hammer and 1864 rear of the hammer.

The stock does not have a visible cartouche but what may be a firing proof (L) is visible rear of the trigger plate. There are multiple insignificant compression dents, scratches and dings throughout its length. It has been cleaned and waxed.

There is repaired damage to the barrel and stock about 13” or 14” from the muzzle and I can only speculate on how and when the damage occurred but it looks like a dent was raised in the barrel. The nickel has thinned enough in the damaged area that it is hard to tell if it was repaired before or after the plating. There are file marks on the exterior of the barrel at this point. The surface of the barrel at the repair point is slightly convex. There does not appear to be any noticeable distortion of the rifling with a bore scope inspection. There is no change of feel or resistance when drawing a tight patch past the damaged area. The stock was damaged by the same strike that damaged the barrel. The stock has a repair on the right side rear of the front barrel band. It is centered about 6” rear of the front barrel band where the file marks are visible on the barrel. Cracks that are visible from the inside run forward about 3” and rearward about 6”. The repaired wood appears to have been broken outward from left to right.

The ram rod has the proper single retaining hump.

The cam latch has squared corners.

The rear sight has the large V sighting notches.

The reference marks on the receiver and barrel are in perfect alignment.

The lower butt plate screw is blued, not plated.

None of the lock assembly parts are plated. The lock plate has remnants of the black finish and the hammer is color case hardened.

The rear sling swivel is in a fixed position because it was permanently attached to the trigger bow when it was plated, this in effect welding it in position. It is at an angle of about 80 degrees relative to the trigger plate.

Other Markings

U right side of both barrel bands

US butt plate tang

X barrel above the reference mark

P barrel below the reference mark

U bottom rear of the receiver

1, 2 breech screw

D top rear of the barrel at the receiver

C barrel under the rear sight

& bottom rear of the breech block

1, V, 8 trigger plate

N, A trigger bow

R trigger

16 main spring base end

5 main spring hook end

K sear spring

D sear

L bridle

3 tumbler

5 stirrup

G, E, H, Z, 2, 6 back of lock plate

Head space Go = .070” No Go =.075” .071”